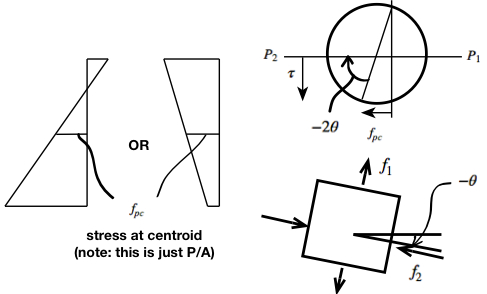

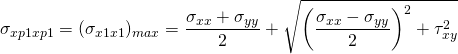

Recall from ‘Mechanics of Elastic Materials’:

(1)

Using our notation in the above diagrams, with all quantities taken as positive:

(2)

(3)

As the axial compressive stress increases, the shear stress required to cause cracking will increase and the inclination of the cracks to the longitudinal axis will decrease.

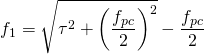

Initial web-shear cracking for prestressed members:

![]()

where ![]() is the vertical component of the PT

is the vertical component of the PT

![]()

![]() is essentially

is essentially ![]() , and adding

, and adding ![]() captures the idea that a greater PT force increases shear capacity.

captures the idea that a greater PT force increases shear capacity.

Initial flexure-shear cracking for prestressed members:

![]()

![]() , here, since we’re assuming uncracked behavior

, here, since we’re assuming uncracked behavior

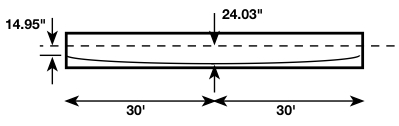

Note: ![]() is NOT constant along the length of the beam, except for beams with tendons of constant eccentricity.

is NOT constant along the length of the beam, except for beams with tendons of constant eccentricity.

![]() , else use

, else use ![]() in the above equations

in the above equations

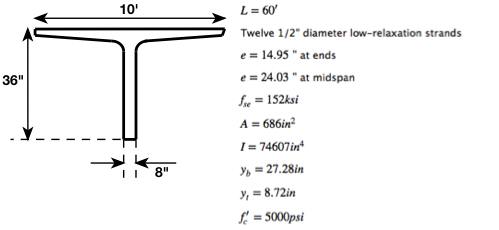

e.x. – estimating diagonal cracking shears – stirrups considered effectively absent

Web-shear cracking:

![]()

where ![]()

![]()

![]()

![]()

We now need to determine the uniform load w that causes a shear of ![]() at a location of

at a location of ![]() from midspan.

from midspan.

Note: The beam can be assumed to rest on a bearing pad of 8”.

50 strand diameters is ![]() . The distance of 50 strand diameters is typically taken from the far end of the beam, while the distance at which BMDs and SFDs typically start, assumes the origin to be at the center of the support i.e. the center of the bearing pad, rather than the far end of the beam. Thus,

. The distance of 50 strand diameters is typically taken from the far end of the beam, while the distance at which BMDs and SFDs typically start, assumes the origin to be at the center of the support i.e. the center of the bearing pad, rather than the far end of the beam. Thus, ![]() , or

, or ![]() , which is the distance from the center of the support, which is the distance of most interest to us.

, which is the distance from the center of the support, which is the distance of most interest to us.

This is how we obtained the value of ![]() from midspan for the following calculations.

from midspan for the following calculations.

Now, imagine looking at a FBD of the middle ![]() :

:

(4) ![]()

Flexure-shear cracking:

![]()

![]()

![]()

The moment-to-shear ratio at a distance of x = ![]() from the center of the bearing pad:

from the center of the bearing pad:

(5) ![]()

![]()

![]()

![]()

where ![]() ,

, ![]() , and

, and ![]()

The load w, required to cause this shear is:

![]()

We can repeat the above calculations for a number of different locations along the length of the beam, and tabulate.

Typically, (1) controls near the support and (2) controls away from the support, though not necessarily at midspan, since ![]() increases towards midspan for draped or harped tendons.

increases towards midspan for draped or harped tendons.

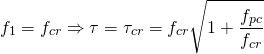

The previous procedure for calculating ![]() (

(![]() and

and ![]() ) must be used if the effective prestress force is less than 40% of the tensile strength of the tendons. Typically, we are above 40%, in which case the following single formula for

) must be used if the effective prestress force is less than 40% of the tensile strength of the tendons. Typically, we are above 40%, in which case the following single formula for ![]() can be used:

can be used:

(6) ![]()

The following procedure will assume that the effective prestress force is greater than 40% of the tensile strength of the tendons.

Typical Shear Design: Step-By-Step

Section dimensions assumed to have been calculated based on other criteria. Loads known.

![]() Choose stirrup size – if #3, then

Choose stirrup size – if #3, then ![]()

Choose a distance x along the beam. Calculate ![]() and

and ![]() at our distance x.

at our distance x.

We can start with the location of maximum shear force ![]() .

.

Calculate ![]() from

from ![]()

(![]() was the upper limit for RC design)

was the upper limit for RC design)

![]() , the ‘simplified’ formula for

, the ‘simplified’ formula for ![]() in RC design, can be taken here as a lower limit.

in RC design, can be taken here as a lower limit.

(7) ![]()

For pre-tensioned members, ![]() must not exceed

must not exceed ![]() within the transfer length.

within the transfer length.

We want to conservatively account for the lack of prestressing effectiveness (force ![]() , and

, and ![]() , which depends on the prestressing magnitude and location) near the supports. There is no

, which depends on the prestressing magnitude and location) near the supports. There is no ![]() or

or ![]() term in the above equation for

term in the above equation for ![]() , but those terms are present in

, but those terms are present in ![]() and

and ![]() , hence the logic behind the aforementioned criteria involving

, hence the logic behind the aforementioned criteria involving ![]() .

.

If ![]() , then solve for

, then solve for ![]() from

from ![]()

![]() no stirrups needed

no stirrups needed

![]() solve for

solve for ![]() from

from ![]() or

or ![]() , whichever is smaller

, whichever is smaller

Calculate ![]() and

and ![]() .

.

If ![]() , then check

, then check ![]() and

and ![]() .

.

If ![]() , then check

, then check ![]() and

and ![]() .

.

If ![]() , then we need to go back to the very beginning and choose a new section

, then we need to go back to the very beginning and choose a new section ![]() .

.

Check ![]()

Check ![]()

If any are violated, decrease ![]() ; take a new

; take a new ![]() and repeat, starting with a new

and repeat, starting with a new ![]() . If more than one check is violated, use the smaller

. If more than one check is violated, use the smaller ![]() value.

value.

Repeat the procedure for various sections along the beam. Sections with a different ![]() and

and ![]() .

.

Finding ![]() from

from ![]() criteria, then finding

criteria, then finding ![]() , is an alternate approach;

, is an alternate approach;

The web steel volume is the same either way.

The former approached outline above in detail is generally used, since having many different stirrup sizes (different ![]() ), would be a hassle. The exact arrangement is always up to the design engineer. Safety and ease of construction should be taken into consideration.

), would be a hassle. The exact arrangement is always up to the design engineer. Safety and ease of construction should be taken into consideration.