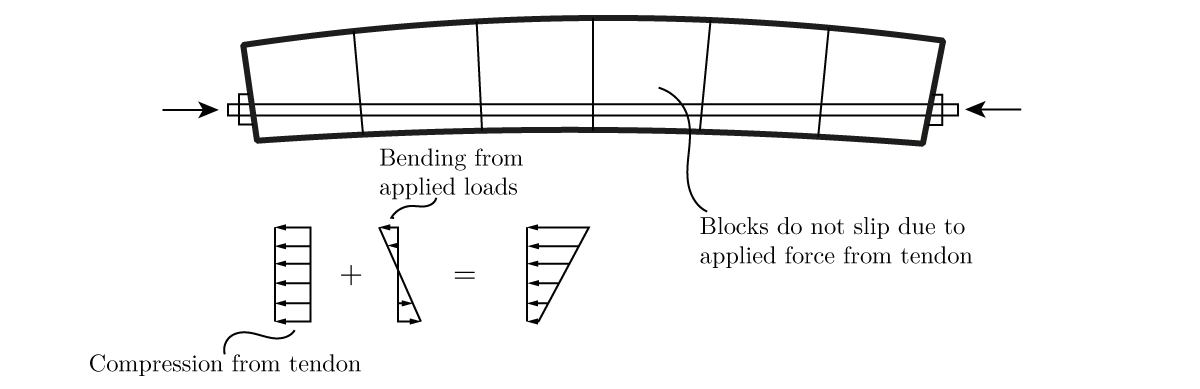

By controlling the amount of prestress, a structural system can be made either flexible [portal frame], or rigid [floor slab] without influencing its strength.

Prestressed, pre-tensioned, tendons are tensioned by a jack without any concrete. Then, concrete is poured, allowed to set and bond, at which time the ends are cut and the beam becomes instantly stressed by the tendons. Service loads can then be applied.

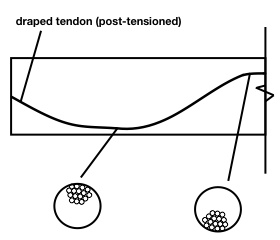

Prestressed, post-tensioned, tendons are tensioned by a jack after the concrete has already cured (but a duct is installed such that the concrete is unbonded to the prestressing), at which time the tendons are tensioned by means of a hydraulic jack, and the beam becomes stressed. Grout may or may not then infill the ducts. Grouting should typically be performed, to minimize the chance of a single tendon rupture causing catastrophic failure of the member. Service loads can then be applied.

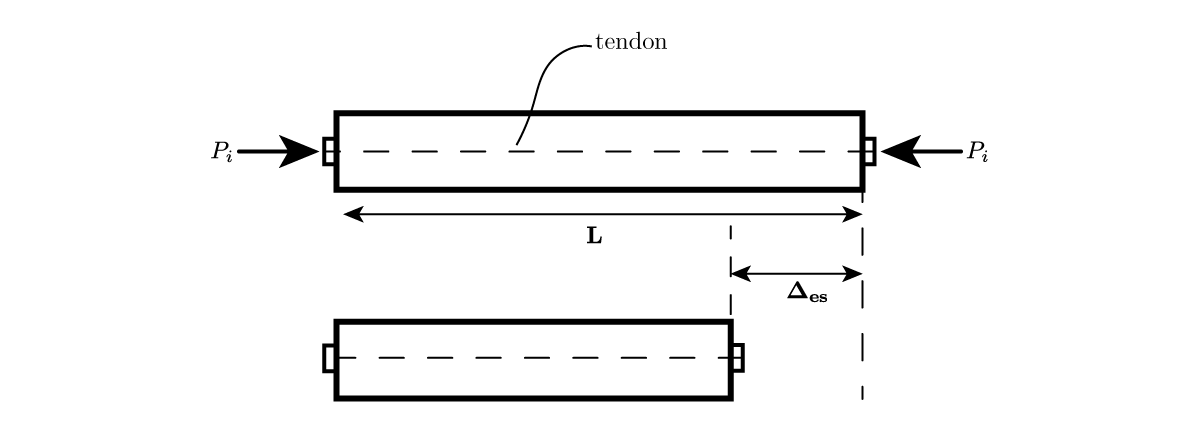

Post-tensioning minimizes losses in prestress that are a result of concrete shrinkage. The only prestress loss due to shrinkage would come as a result of duct grout shrinkage. In addition, for pre-tensioned beams, ![]() because of concrete compressive strain at the instant that the tendons transfer the compressive force to the concrete beam (see figure below).

because of concrete compressive strain at the instant that the tendons transfer the compressive force to the concrete beam (see figure below).

More explicitly, ![]()

For post-tensioned beams, with all of the tendons jacked simultaneously, the concrete will strain, but our value for ![]() will be equal to our

will be equal to our ![]() , since the tendon force

, since the tendon force ![]() is essentially (neglecting ‘anchor set’) measured after the load is applied to the beam (after the hydraulic jacking is complete). This is in contrast to pre-tensioning, where

is essentially (neglecting ‘anchor set’) measured after the load is applied to the beam (after the hydraulic jacking is complete). This is in contrast to pre-tensioning, where ![]() is measured before the load is applied to the beam (before the tendons are ‘cut’).

is measured before the load is applied to the beam (before the tendons are ‘cut’).

However, post-tensioning is more prone to anchorage zone failure, as the beam is stressed by the tendons, since large compressive forces (especially when the tendons are un-bonded) occur only at the ends of the beam. Pre-tensioned beams transfer the tendon force to the concrete through friction, within a given ‘transfer length’ near the ends of the beam, rather than at a single point. This distinct feature of pre-tensioned beams is analogous to the development length for concrete mild-reinforced members, and should not be confused with ‘friction losses’ in post-tensioned beams.

Losses due to friction are unavoidable for post-tensioned beams. This will be explained in detail in the section on friction losses.

In general, either method (pre or post-tensioning) can be used, depending on application.

Suffice to say, the effective prestressing force, ![]() , is less than the initial prestressing force

, is less than the initial prestressing force ![]() , such that

, such that ![]() .

.

A couple of other notes about pre-tensioning and post-tensioning:

Where pre-tensioning is concerned, ‘hold-downs’ to form the ‘draped’ shape of the tension, which we will talk about later, are expensive. Typically, pre-tensioned beams will use a ‘harped’ shape, which is marginally less efficient for most beams loading conditions.

One reason for the grouting of post-tensioned beams is to avoid a condition where a single tendon failure point would cause total failure, i.e. a tendon puncture from a careless jack hammer.

The center of gravity (c.g.) of the tendon and the c.g. of the duct are different.

The center of gravity (c.g.) of the tendon and the c.g. of the duct are different.

NOT accounting for this would essentially be unconservative.