Stress, like strain, has intuitive physical meaning for engineers. Stress can come in the form of tension, compression, or shear. The forces present on one or more elements within a body are found from stresses by integrating over areas, and quantities such as moments, though not found naturally in FEA, can be easily back-calculated from stresses as well.

note: While “moments” are essential in classical structural analysis and design, from an FEA point-of-view (“solid” elements), they are an unnecessary simplification and will not be discussed in this text.

Forces (or stresses) within a body are found from externally applied forces, even if the objective is to find deformations. The stiffness of the material, which relates internal force and internal deformation, determines any deformations of interest that result from externally applied forces and body forces. This may all be familiar, since classical, “analytical,” structural analysis methods also require stiffness relationships that relate internal forces to displacements or moments to rotations. In FEA, stress and strain are used, directly, for this purpose, and the “stiffness” relationship that relates them is called a constitutive relationship. This will be discussed in great detail beginning in the next chapter. This chapter will just focus on stress. Specifically, we’ll consider how to physically interpret a stress tensor, along with some different measures of stress that are commonly used, and how they each handle considerations like large deformations and rigid body rotations.

The “Cauchy” stress is a second-order, symmetric, tensor that contains six independent components: ![]() axial stresses and

axial stresses and ![]() shear stresses. More on the physical description of

shear stresses. More on the physical description of ![]() can be found in Appendix B.1, where

can be found in Appendix B.1, where ![]() is essentially derived. An alternative derivation of the stress tensor, which doesn’t use index notation, as well as an explanation of the tensor’s symmetry, can be found in [Boresi] or [Ugural].

is essentially derived. An alternative derivation of the stress tensor, which doesn’t use index notation, as well as an explanation of the tensor’s symmetry, can be found in [Boresi] or [Ugural].

Simple 2D e.x.

Imagine that at some point within some structure, we’ve determined the stresses to be (ignore units):

![]()

![]()

![]()

![]()

![]()

![]()

To find the stresses, at, say, ![]() , we could use Mohr’s Circle or the transformation equations from undergraduate “Mechanics of Materials.”

, we could use Mohr’s Circle or the transformation equations from undergraduate “Mechanics of Materials.”

Solution for the normal stress at ![]() for example:

for example:

![]() (skipped work)

(skipped work)

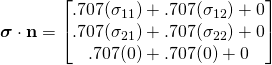

Using the stress tensor method instead:

![]()

![]() “

“![]() ”

”![]() , as expected

, as expected

- A. C. Ugural and S. K. Fenster, Advanced Mechanics of Materials and Applied Elasticity, Pearson Education, 2011.

[Bibtex]@book{Ugural, title={Advanced {M}echanics of {M}aterials and {A}pplied {E}lasticity}, author={Ugural, Ansel C and Fenster, Saul K}, year={2011}, publisher={Pearson Education} } - A. P. Boresi, R. J. Schmidt, and O. M. Sidebottom, Advanced mechanics of materials, Wiley New York, 1993, vol. 5.

[Bibtex]@book{Boresi, title={Advanced mechanics of materials}, author={Boresi, Arthur Peter and Schmidt, Richard Joseph and Sidebottom, Omar M}, volume={5}, year={1993}, publisher={Wiley New York} }