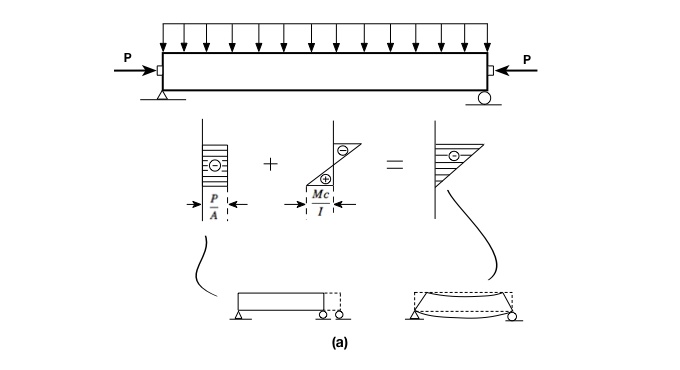

Bending stresses from prestressing:

Top:

(1) ![]()

Bottom:

(2) ![]()

note: The beam will have flexural deformation under the applied loading. However, the beam will not be in tension, because, in the case shown above, the bottom fiber will merely have returned to its original length (length prior to prestress or other applied loads). Note also that prestressing tendons are always high strength steel, so that the applied strain is large and thus creep from, say, gravity, has less influence. Early attempts at prestressing were unsuccessful (under long-term loading) because high strength steel was not used.

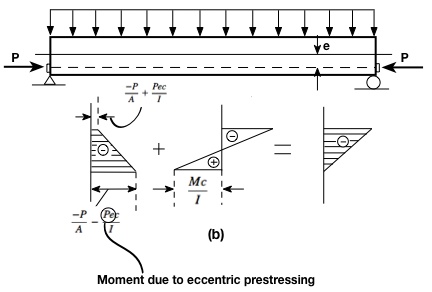

Note the significantly larger applied moment compared with (a). Yet, both (a) and (b) result in the same bending stresses (same deflected shape).

The eccentricity essentially raises the tensile stress capacity of the beam to take external load.

From (a) we can see that the prestressing can either eliminate tension totally (even inducing compression under service loads), or permit a level of tensile stress within the allowable limit. However, from (a) we can also see that the compressive stress capacity of the beam to take a substantial external load is essentially reduced by the prestressing force. In order to avoid this limitation, which presumably exists under service loads, the prestressing tendon is placed eccentrically below the neutral axis.

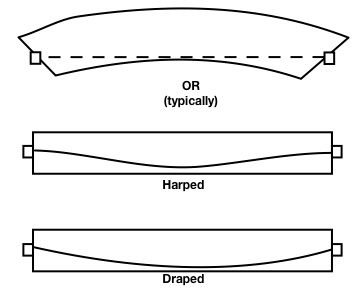

Often, the tendon would be draped or harped, such that the prestressing force is below the neutral axis at midspan, but at the neutral axis (simply supported beam) or above the neutral axis (continuous beam) at the supports.

(3) ![]()

(4) ![]()

At the supports (which are typically continuous), the external prestressing load creates tension at the top and compression at the bottom of the section. Thus, if the prestress c.g. line were to remain below the neutral axis at the support, then this tension at the top of the section would be exacerbated under service loads. To mitigate this problem, the member can be cambered in such a way so as to bring the prestress c.g. above the neutral axis, at the support, while still enabling the prestress c.g. to remain below the neutral axis at midspan. Rather than cambering the beam in this way, more commonly, the tendons are harped (using ‘hold-downs’ in the pre-tensioning bed) or draped (using a post-tensioning duct).

note: at midspan, we are RELYING on the self-weight of the member to counteract some of the negative prestressing moment. Thus, prestressed beams should NEVER be laid flat on the ground or turned upright, etc., during transportation or erection, or catastrophic failure can result.

If ![]() is the initial prestressing force before stress losses, and

is the initial prestressing force before stress losses, and ![]() is the effective prestressing force after losses, then:

is the effective prestressing force after losses, then:

(5) ![]()

eq. (1) and (2) can be rewritten more precisely to include ![]() (also,

(also, ![]() )

)

(6) ![]()

(7) ![]()

If there is still any significant tension in the beam, then bonded non-prestressed reinforcement (mild reinforcement) is proportioned to resist the total tensile force.

There are no new equations for draped or harped tendons. At midspan, there is no vertical component of tendon force. The horizontal component is constant throughout the length of the tendon (ignoring friction), and the vertical component does not contribute to capacity, since we’re analyzing flexure alone when we look at the cross-section as a whole.

So, at this point, there is still a lot to cover, but what if we have a beam loaded with and we’d like to know the required tendon force, ![]() , and eccentricity,

, and eccentricity, ![]() , at midspan. Assume simple supports, such that

, at midspan. Assume simple supports, such that ![]() at the ends. Assume

at the ends. Assume ![]() ;

; ![]()

(8) ![]()

(9) ![]()

2 equations, 2 unknowns ![]() and

and ![]()

Of course, this assumes that ![]() is known, which in practice, we would want to determine analytically.

is known, which in practice, we would want to determine analytically.