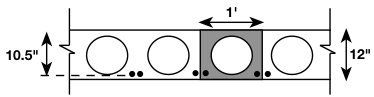

Post-tensioned, un-bonded one-way slab with draped tendons (midspan moments will be assumed to control)

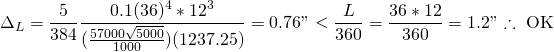

![]() , where

, where ![]() is the area of the entire section shown above and

is the area of the entire section shown above and ![]() is the shaded area.

is the shaded area.

![]() , which is the moment of inertia of the shaded area

, which is the moment of inertia of the shaded area

![]()

c = 6”

![]()

![]()

![]() , low-relaxation

, low-relaxation ![]()

![]()

![]()

![]()

Friction, anchor set, long-term losses

A detailed friction analysis could be performed, as done in an earlier section, but here we will just estimate ![]() as

as ![]() , and

, and ![]() as

as ![]() .

.

Finding ![]()

member self-weight ![]() (per foot width)

(per foot width)

![]() (per foot width)

(per foot width)

![]() (per foot width)

(per foot width)

![]() (per foor width, working stress)

(per foor width, working stress)

![]()

![]()

(1) ![]()

Note: this is based on bottom tension at service

![]() (per foot width)

(per foot width)

Also, for strength,

![]() (per foot width, LRFD)

(per foot width, LRFD)

![]()

Try two ![]() diameter strands;

diameter strands; ![]() (per foot width)

(per foot width)

Check top tension at transfer

![]()

(2) ![]()

where ![]() ,

, ![]() ,

,

![]()

(3) ![]()

Check bottom compression at transfer

![]()

![]()

![]()

![]()

Check top compression service

![]()

![]()

![]()

![]()

Code specified minimum mild steel in slab

![]() (per foot width)

(per foot width)

Choose one #4 bar per foot ![]()

![]() (per foot width)

(per foot width)

Strength

For members with unbonded tendons:

For members with span-to-depth ratios of 35 or less,

(4) ![]()

Else,

(5) ![]()

where ![]()

For our example,

![]()

![]()

![]()

There are two checks:

![]() and

and ![]()

(6) ![]()

(7) ![]()

(8) ![]()

(9) ![]()

(10) ![]()

(11) ![]()

Check Ductility

![]()

![]()

(12) ![]()

Quick deflection check

(13)